Reasons Why Most Companies Use 3D Printing

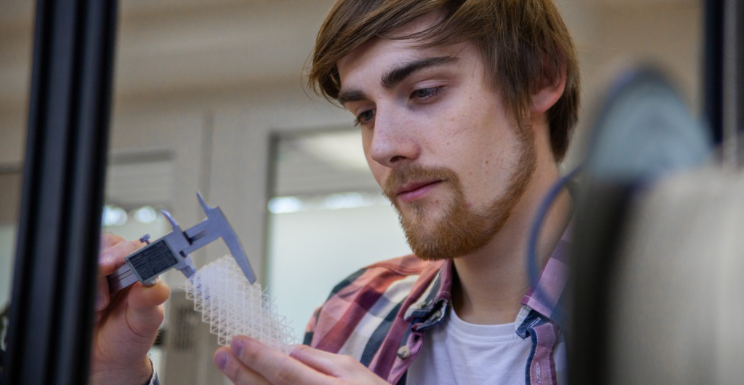

A 3D printer creates tens of thousands or hundreds of movements within a workspace. Hence, 3d printing miniatures (or your choice) have been used in the manufacturing place.

What Is 3D Printing

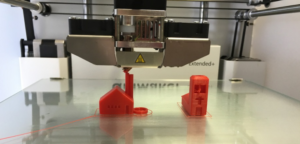

Each time a 3D printer produces a pass, it follows computer instructions and leaves a layer of a substance that eventually ends up in a finished three-dimensional product. While traditional manufacturing takes a block of raw substance that is shaped or dyed to create a finished product, 3D Printing advertises materials at each step to create a finished product. For this reason, 3D Printing is popularly known as “additive manufacturing.” 3D printers can produce a wide collection of finished products, from the simplest to the most complex.

Each time a 3D printer produces a pass, it follows computer instructions and leaves a layer of a substance that eventually ends up in a finished three-dimensional product. While traditional manufacturing takes a block of raw substance that is shaped or dyed to create a finished product, 3D Printing advertises materials at each step to create a finished product. For this reason, 3D Printing is popularly known as “additive manufacturing.” 3D printers can produce a wide collection of finished products, from the simplest to the most complex.

What is new is the increased acceptance and use in the manufacture of finished products. Stereolithography is the technical term that gave Hull what is commonly known as 3D Printing. 3D Printing has slowly evolved from its original modest uses to the more complex applications of today. Although 3D Printing is still used to create prototypes for product development, improvements in computers have made 3D Printing a technology that can produce finished products on demand.

What is new is the increased acceptance and use in the manufacture of finished products. Stereolithography is the technical term that gave Hull what is commonly known as 3D Printing. 3D Printing has slowly evolved from its original modest uses to the more complex applications of today. Although 3D Printing is still used to create prototypes for product development, improvements in computers have made 3D Printing a technology that can produce finished products on demand.

What Are the Benefits

Several companies are manufacturing 3D printers and providing 3D printing-related services in the growing number of manufacturers using 3D printing technology in crop production. The company is turning to 3D Printing to reduce costs and simplify the manufacturing process. So the supplier is working with 3D printer manufacturers to develop new production printers that are on par with mass production. To get an idea of how the gas nozzle of a jet engine is created from a 3D layer, it takes about 3,000 iterations to make General Electric’s gas nozzle with a 3D printer to produce the final object.

Several companies are manufacturing 3D printers and providing 3D printing-related services in the growing number of manufacturers using 3D printing technology in crop production. The company is turning to 3D Printing to reduce costs and simplify the manufacturing process. So the supplier is working with 3D printer manufacturers to develop new production printers that are on par with mass production. To get an idea of how the gas nozzle of a jet engine is created from a 3D layer, it takes about 3,000 iterations to make General Electric’s gas nozzle with a 3D printer to produce the final object.

To ensure this, General Electric must install 3D printers that can efficiently perform the established task. The printers need instructions from a computer program that tells them exactly where to place the raw materials each time the 3D printers pass through the workstation. The result so far is a gasoline nozzle for a jet engine. The growth prospects for the 3D printing industry over the next few years are pretty solid. 3D Printing has been gaining traction for several decades. General Electric’s announcement of its intention to use 3D printers to mass-produce fuel nozzles for jet engines has boosted the entire industry.